How the Gulf states are using tech to build net-zero and future-fit manufacturing industries

In a net zero future, countries like Bahrain view advanced and net zero manufacturing as a major source of income. Image: Getty Images/iStockphoto

Ahmed Sultan

Executive Director – International Offices & Business Development (Manufacturing, Transport & Logistics), Bahrain Economic Development Board

Get involved with our crowdsourced digital platform to deliver impact at scale

Stay up to date:

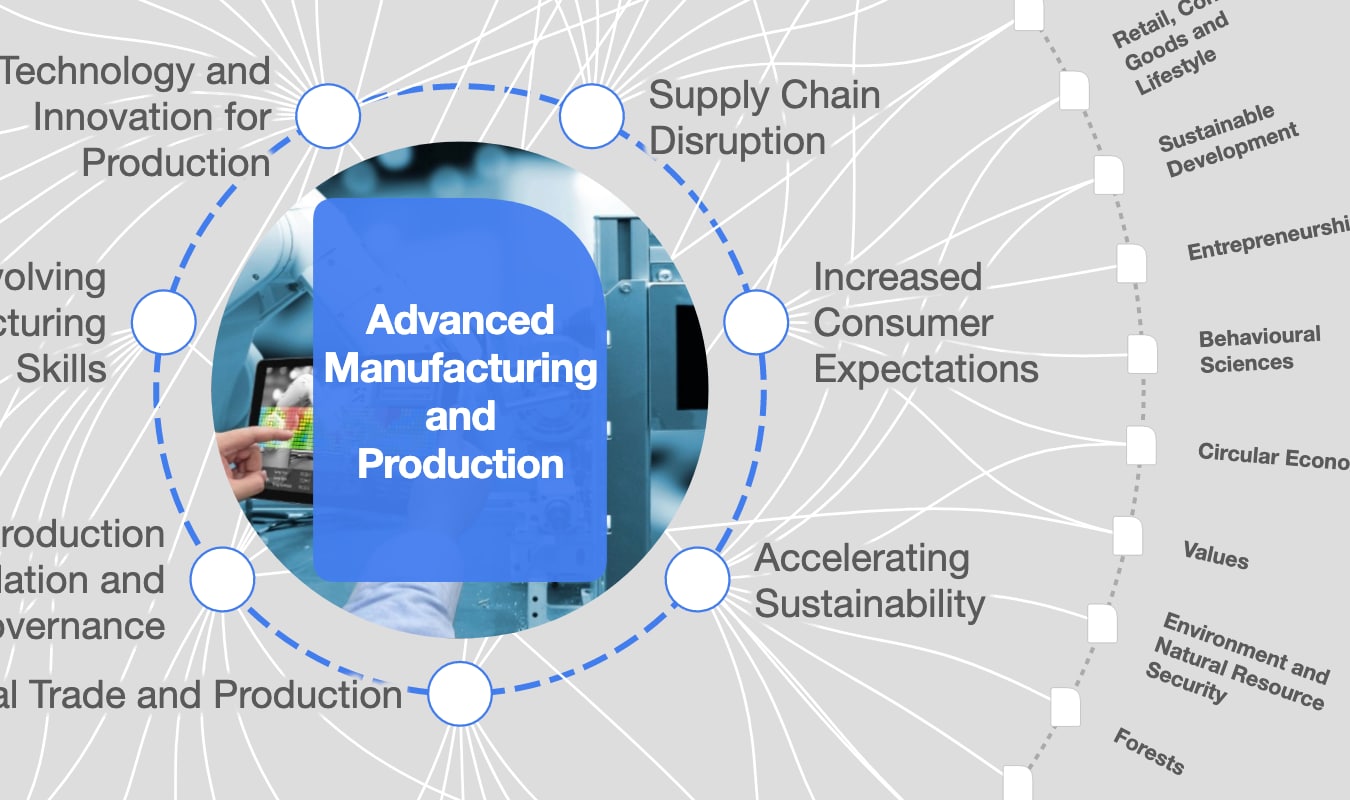

Advanced Manufacturing

Listen to the article

- The industrial sector, which includes manufacturing, accounted for 38% of global emissions in 2021.

- Countries across the GCC are seeking to build modern, advanced and productive manufacturing industries.

- Countries like Bahrain are using cutting-edge technology, such as data analytics and renewable energy generation, and public-private collaboration to build future-fit and net zero manufacturing industries.

Sustained, robust and cooperative action on climate change has never been more important. There is international scientific consensus on the need to cut global greenhouse gas emissions significantly and achieve net zero.

And yet, the events of 2022 have shown that there is still a long way to go if we are going to make net zero a reality.

The Solutions Day of COP27 is, therefore, a vital forum for identifying and acting on actionable ways to confront the mounting climate crisis.

From green national budgets, to making cities and transport sustainable, to waste management and plastic alternatives, change at every level will be required to effectively combat the climate emergency.

The manufacturing sector is no different.

Sustainability in manufacturing

Everyone and every sector has a role to play in decarbonising the global economy, but the participation of the manufacturing sector is particularly important. The industrial sector, which includes manufacturing, accounted for 38% of global emissions in 2021 and fossil fuels remain the dominant source of energy in this area.

The industrial sector is especially important to the economies of Gulf Cooperation Council (GCC) countries, and so too are efforts to make the sector sustainable.

These decarbonization efforts are country dependent and thus look different for each GCC country. For Bahrain, for example, the manufacturing sector is the second largest non-oil sector in the country, and so is a crucial target in the country’s efforts to cut its emissions by 30% by 2035 and achieve net zero emissions by 2060.

Bahrain is leveraging the private sector to assist in efforts to meet net zero. In 2018, it launched the Fiscal Balance Program, which aimed to boost revenue from non-oil sources through government partnerships with the private sector. The Kingdom is keenly aware that it needs to move away from fossil fuel production — this awareness led it to creating the Ministry for Sustainable Development, which aims to promote not just environmental sustainability, but fiscal and economic sustainability across the Gulf region. It is also an important part of the Kingdom’s Industrial Sector Strategy — a pillar of its Economic Recovery Plan — which aims to boost renewable energy sectors including “blue and green hydrogen” as part of its net zero commitment.

Routes to net zero manufacturing in the Gulf

Reducing manufacturing-related emissions requires creativity and ambition. Bahrain, like many other GCC states, seeks to build an advanced industry focused on technological innovation and sustainability, embedding the principles of a circular economy. That means creating the environment for the private sector to let its innovations flourish is crucial.

Take aluminium, for example. The world produces roughly 65 million tonnes annually and creates one million tonnes of aluminium dross, which is a by-product of the manufacturing process riddled with impurities. Dross recycling is a well-established practice for aluminium manufacturers, but conventional methods still produce a sizeable carbon footprint. Fortunately, TAHA International is developing the capability to recycle aluminium dross with almost no carbon emissions, utilising a technique that vastly outperforms other methods of dross recycling and results in 80% fewer emissions, according to analysis conducted by EY for TAHA.

The transformative effects of solar power are also being recognised across the Gulf. Solar power is an obvious choice for domestic energy supply but the manufacture of solar technology is also gaining importance in the region. From the construction of a 100-MW solar park on top of a landfill site in Bahrain to moves by existing manufacturers like Arla Foods to green their electricity supply, the Gulf states are driving the installation of solar technology. Of crucial importance is the cooperation between private and public sectors — in the region’s smaller and highly urbanised countries, with little free land to spare, the hosting of solar panels by private corporations helps governments to meet their sustainability targets.

Using cloud technologies to increase efficiencies is also an important part of sustainable action. Plugging data capture and analysis tools into the energy infrastructure of private and public companies alike helps them to better understand energy usage and take action to make manufacturing facilities more efficient. Mondelēz International, for example, has developed a cloud-based technology that helps the company efficiently monitor the use of water, electricity and natural gas at its Bahrain factory. The data is available in real time and can be readily compared with sustainability benchmarks, with positive improvements already being noted — CO2 emissions from the factory were down 65% in 2020 compared to 2018, with a 70% reduction in total waste for the same period.

Technology and sustainable manufacturing

Green technologies will be a crucial part of the race for countries and corporations to achieve net zero.

The manufacturing sector is creating important opportunities for technological and sustainable innovations that will drive this change, especially in the GCC, where the need for robust action on climate change is tacitly understood.

As well as technological solutions, future action on sustainability will be defined by cooperation at all levels of society, across borders and continents. It is not just a financial and economic imperative that we do this — it is vital for the continued functioning of our societies. The future is bright for the GCC's manufacturing industry, and green innovations will help light the way.

Don't miss any update on this topic

Create a free account and access your personalized content collection with our latest publications and analyses.

License and Republishing

World Economic Forum articles may be republished in accordance with the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International Public License, and in accordance with our Terms of Use.

The views expressed in this article are those of the author alone and not the World Economic Forum.

Related topics:

The Agenda Weekly

A weekly update of the most important issues driving the global agenda

You can unsubscribe at any time using the link in our emails. For more details, review our privacy policy.

More on Advanced ManufacturingSee all

Stephanie Wright, Memia Fendri and Kyle Winters

February 13, 2024

Maya Ben Dror and Lena McKnight

January 31, 2024

Dr. Matthew Putman

January 17, 2024

Kyriakos Triantafyllidis and Andreas Hauser

January 16, 2024